My Shopping cart

Rethinking the retail experience

Lockdowns and working from home have had a profound effect on the Australian way of life, including what we expect from a retail experience.

Key points

- Consumer behaviour and expectations have changed dramatically.

- Omni-Channel retailing is required to meet customer demands.

- Retailers need to remain dynamic in their physical and online product offerings.

The new way of shopping

The pandemic is accelerating the trend towards digitisation in the home, in the workplace, in the way services are accessed. Shopping is now done online, and delivery vans are now a regular feature of suburban traffic.

The options for accessing retail services seem endless: there’s home delivery, click and collect, kerbside pick-up as well as the traditional concept of actually browsing and buying from a shopping centre.

But even here there is new technology to navigate like accessing QR codes and registering email and/or phone numbers in order to simply attend shops.

In terms of actual retail sales, the pandemic has prompted a shift in traditional spending patterns. Liquor sales jumped 27 per cent in the year to June 2020, according to ABS estimates1. This compares with growth of just 2 per cent over the previous year.

Other sectors that surged over 2019/20 in terms of retail spending include hardware, electrical and furniture, all up more than 14 per cent over the year.1 It’s a consistent story: the pandemic prompted Australians to transfer spending otherwise tagged to international travel to home improvement, and embellishing and adorning their immediate environment.

More and more frequently, unusual substrates including steel, metal and aluminium are being used in tile or stone installations. Swimming pools, spas, hot tubs, elevator cabs, and cooler floors and walls frequently have a steel surface on which to bond tile. Below are methods to properly install tile to these substrates.

The preferred method for installation over steel is;

- Steel, metal or aluminium substrate must be rigid and meet the maximum allowable standard for deflection of L/360 for ceramic tile or L/480 for stone tile

- Tack weld or mechanically fasten 1.8kg/m2 galvanized or otherwise suitable diamond metal lath over the steel surface in accord with good trade practice to provide an adequate structural connection for this installation and sufficient space for adequate mortar thickness behind.

- Apply a scratch and levelling coat of 3701 Fortified Mortar Bed; or, 3701 Mortar Admix mixed with 226 Thick Bed Mortar to encapsulate and fill the lath.

- After the mortar hardens, HYDRO BAN® may be installed where specified.

- Tile may be installed with 254 Platinum Adhesive, 335 Premium Flexible Adhesive or 4237 Latex Additive mixed with 211 Crete Filler Powder. In areas where a more chemically resistant adhesive is necessary (or when installing water sensitive marble or agglomerate) install with LATAPOXY® 300 Adhesive.

- When tile has set firm, grout with SPECTRALOCK® PRO Premium Grout; or, PERMACOLOR® Grout. For areas subjected to food acids, harsh chemicals or extreme heat use SPECTRALOCK 2000 IG.

Uneven Colouring

Ideally, grout has a consistent colouring from one side of the room to the other. In practice, it is not unusual to see fluctuation in the colour. This issue can be caused by many issues. Most commonly, the error comes from issues mixing the grout. If only half of the bag is used to mix a batch, it is possible for the colour pigment to be uneven from one batch to the next. Also, if extra water is added into a batch of grout to rehydrate it during the job, the colour will be lighter after the water is added. Another common cause is using dirty water or a dirty sponge to wipe off the tiles during grouting or removal of grout haze.

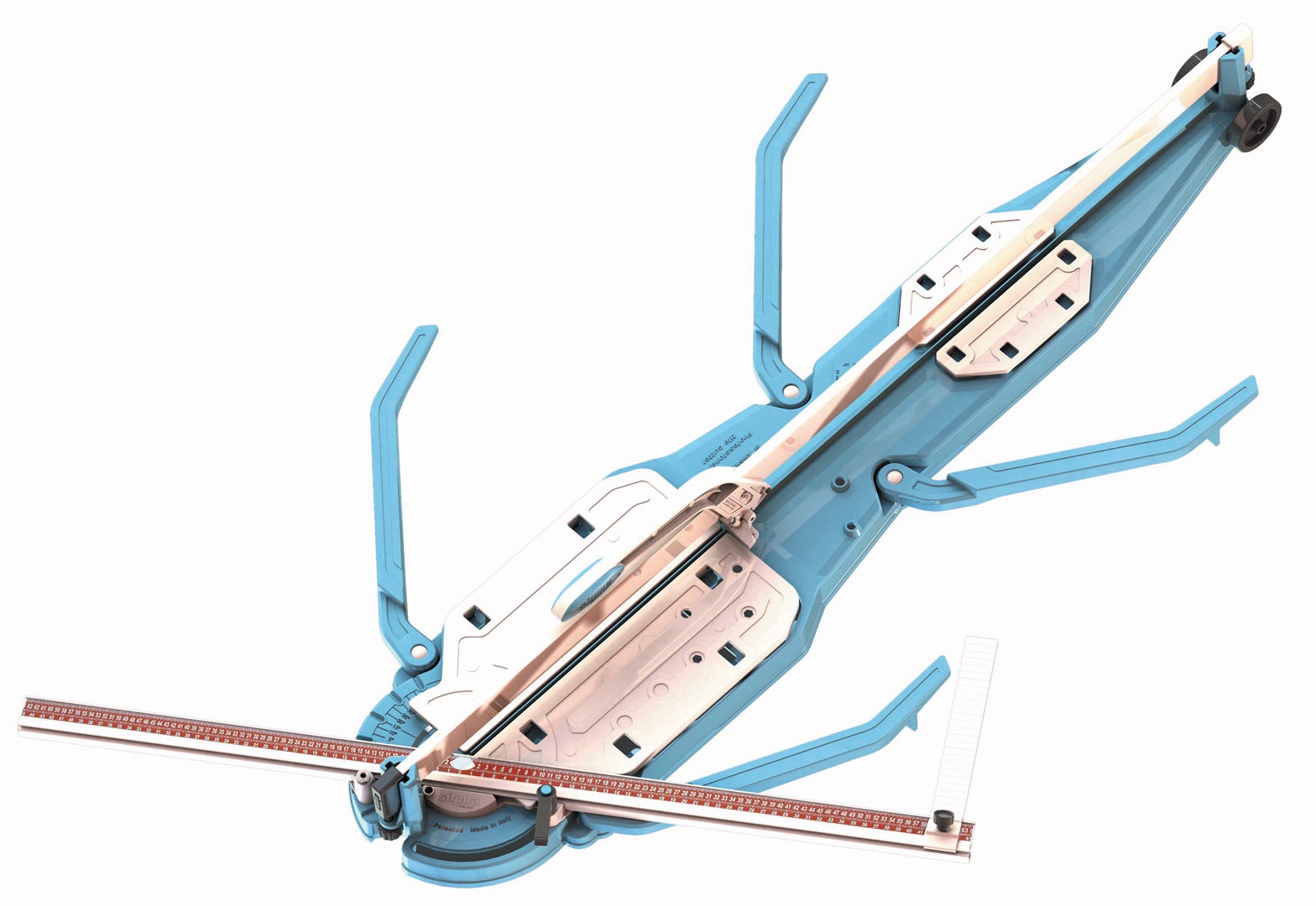

Art3E4M - 127cm Sigma's back in stock! A large push action heavy duty tile cutter with adjustable height settings and a diagonal arm that swivels from 0°-45° in both directions.

Be in quick as this stock won't last!